A sustainable Platform for fabric preservation

senior design researcher & strategist, ia collaborative

Chicago, IL

OVERVIEW

The challenge

A leading consumer packaged goods (CPG) company with two of the top brands in fabric care wanted to define a new product category in laundry. The ask was fairly open-ended: identify a new market opportunity for a product line worth at least $70 million. While it wasn’t specifically asked of us, we also strongly advocated for sustainability considerations to be baked into the new platform.

STAKEHOLDERS

Customers with diversity across:

5 different segments of laundry behaviors and attitudes, from Apathetic Avoiders to Passionate Optimizers

urban and suburban markets

demographics and income levels

Internal stakeholders included:

Research and Development (R&D)

Packaging

Brand

Marketing

My Role

The team included 2 visual designers, a business strategist, and myself. I led the research components of the project.

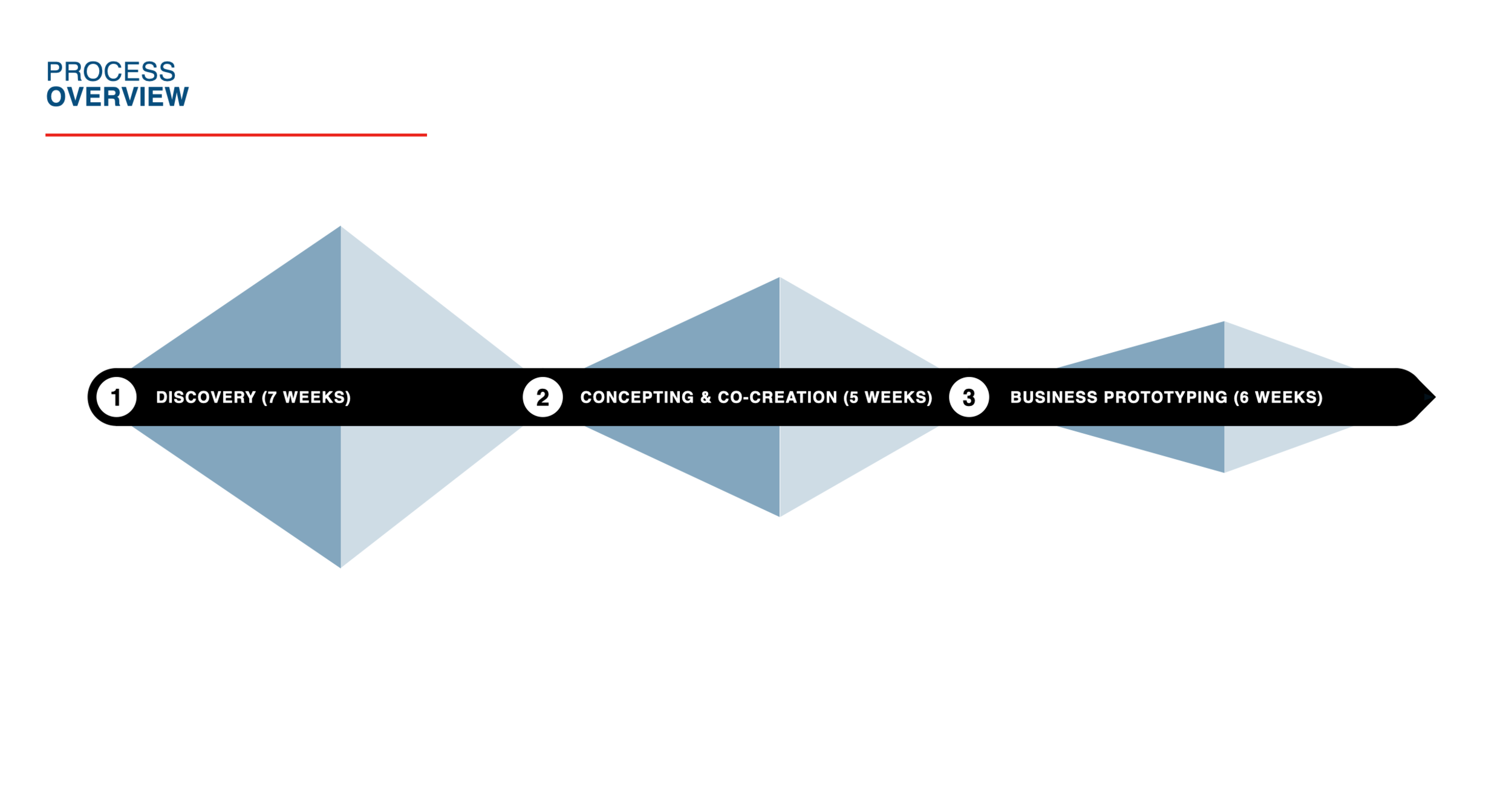

Approach

Discovery research: immersions, observations, visual diary studies, contextual interviews

Co-creation and concept validation: concept testing with low-fidelity prototypes to identify and build upon the most promising concepts

Internal capability assessment: stakeholder interviews across R&D, packaging, and marketing teams

Business prototyping: simulated a business across digital and in-person channels, A/B testing various elements of the business

outcomes

We identified a $150 million market opportunity to preserve fabrics and developed a strategy to capture it, including a roadmap for R&D, branding, and marketing. This strategy established an entire platform of products that work together to continually reinforce the powers of preservation across the fabric care journey. Additionally, we snuck in environmental benefits: these products reduce pollution by (1) keeping microplastic fibers in your fabrics—and out of the oceans, (2) extending the lifetime of your clothing, thereby keeping fabric waste out of the landfill, and (3) decreasing the demand for new clothing purchases, which reduces waste in production and along the supply chain.

exploring the world of laundry

methods

To understand the fabric care landscape and identify pain points and unmet needs:

Immersions in existing laundry products and services to understand competitive offerings

Expert interviews with commercial textile suppliers, hotel cleaning staff, dry cleaners, athletic materials engineers, and fragrance retailers

Visual journals wherein participants documented their fabric care routine with photos and videos for a week

Contextual interviews that included a home tour following the journey of one’s clothing from closet to laundry room and a shop-along for laundry products

key insights

Through our research, we discovered that:

Clothing is about projecting one’s best self, and the purpose of laundry products is to help do that by maximizing the fabric’s lifetime—not only extending the life of one’s clothing, but also keeping it looking like new

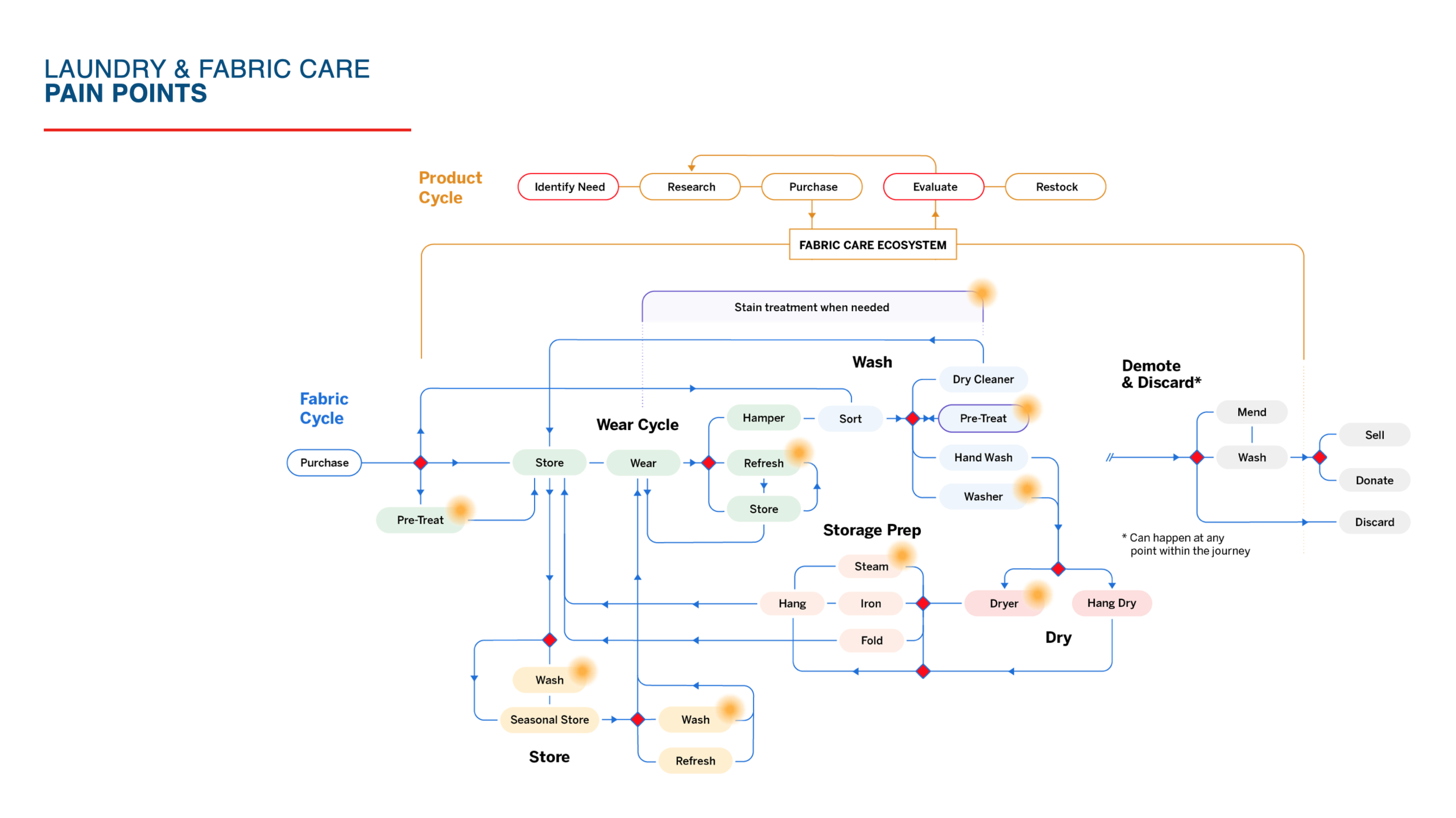

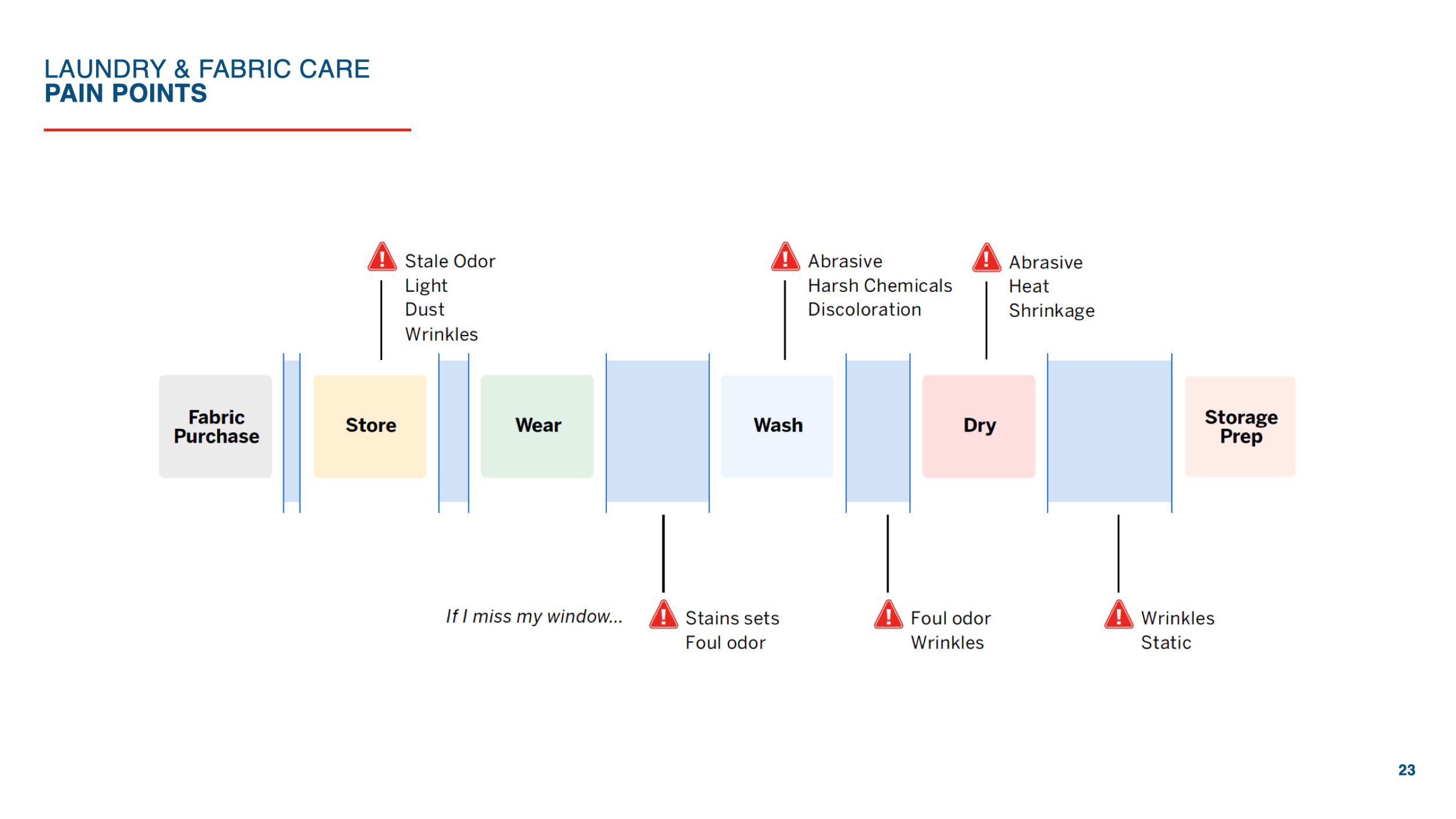

The fabric care process is fragmented with many starts and stops, and missing a key window can result in exacerbating a problem (e.g. a stain setting, odors, wrinkles)

People are just as worried about the harm of care as the harm of wear (in other words, they worry about the damage the washing machine and dryer will do to their clothing)

People do not believe product promises about restoring clothing’s previous state—damage cannot be reversed, but preventing damage is more believable

Many, especially those with young children, are worried about the safety of the products and choose hypoallergenic or natural products when possible or economically feasible

Many consumers have an arsenal of products at the ready to tailor to different use cases, to different types of fabrics or cleaning needs

The purchasing process is very confusing, with an overwhelming number of options, and people feel uncertain in their choices

insight to action: Concept development and testing

Design principles

Based on the above insights, we devised the following design principles to guide ideation:

Build endurance to maximize fabric’s life: strengthen the fabric itself so that it can withstand whatever life throws at it, preventing damage from occurring in the first place

Shepherd people to discover and use care products with confidence: remove uncertainty from the process by educating the customer on how to best care for their fabrics

Equip people to deliver personalized care they can be proud of: different fabrics or types of harm require different solutions, so provide a suite of products that enable the customer to tailor care for every situation

concept development and co-creation

Using the design principles as guidelines (with additional directives within each principle to provide further clarity and guidance), we facilitated a co-creation workshop with key stakeholders to generate as many concepts as possible. We then synthesized and refined these concepts, and together with the client, prioritized the ones we would take forward into testing. To do this prioritization, we had conducted internal stakeholder interviews with the client’s R&D, packaging, and digital teams to understand in-house capabilities. We were then able to assess the options through a feasibility lens, considering not only what was scientifically possible but also what might be cost-efficient to produce and launch.

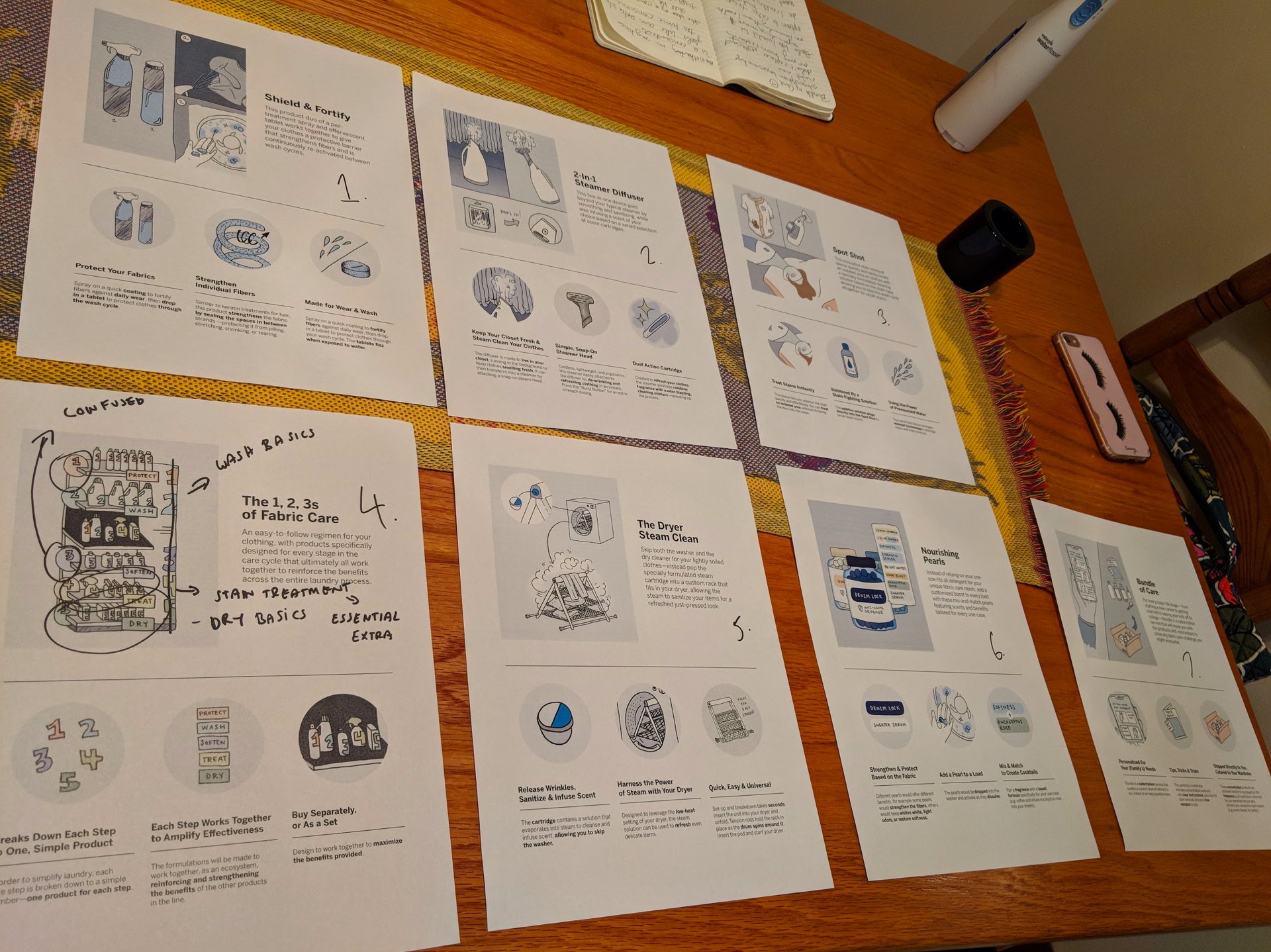

We tested the top 7 concepts with customers in two markets, Philadelphia and Atlanta, using the following low-fidelity stimuli:

Concept cards that included an illustrated storyboard to explain the use case and functionality for each idea. After reviewing every card, the participants would rank these from most likely to purchase to least likely to purchase.

Physical form factors, including containers, formulations (e.g. powder, liquid, tablets), etc., for participants to get a more tangible understanding of the concepts in the illustrations, as well as to help them specify preferences for or modifications to those concepts.

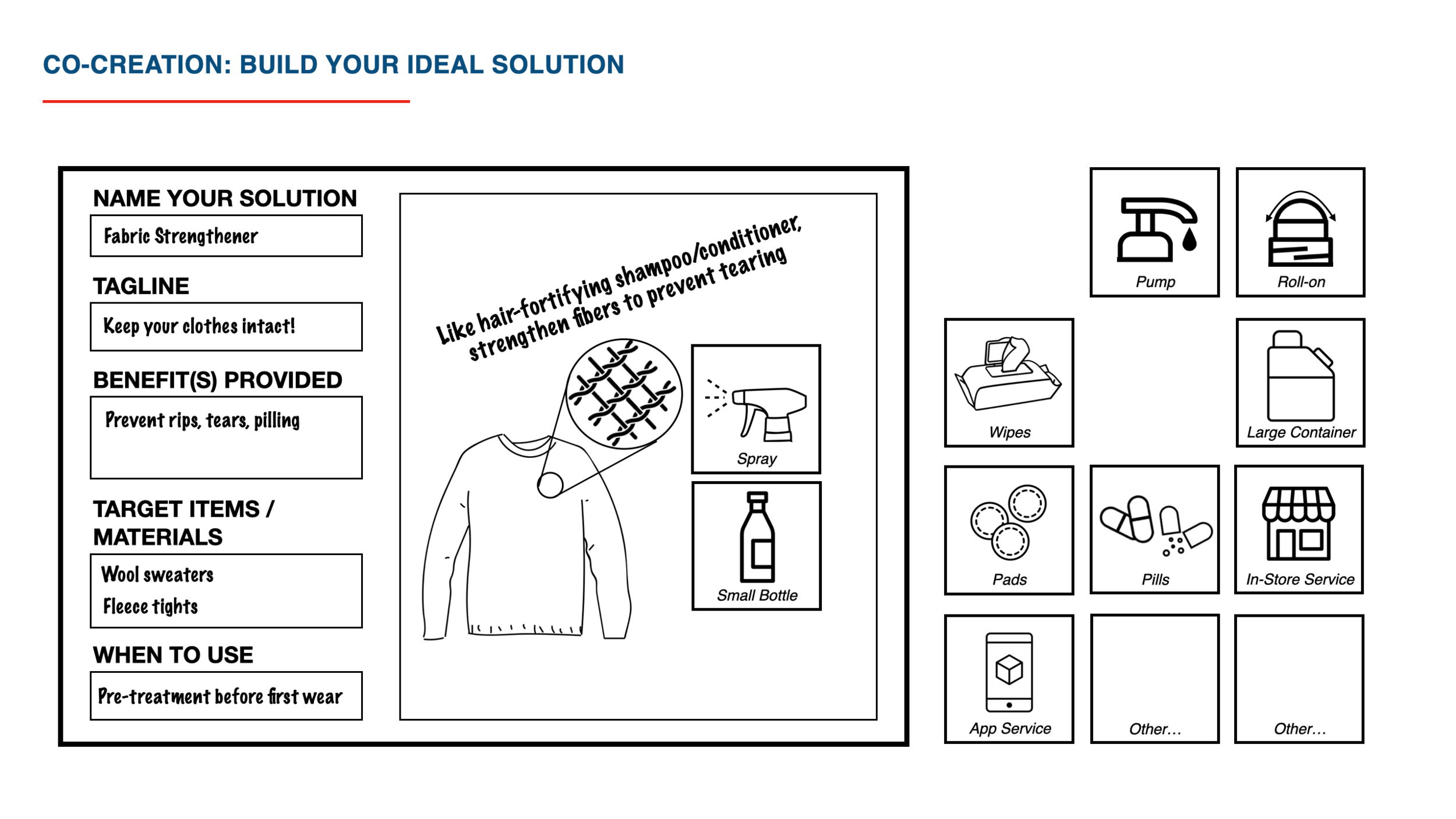

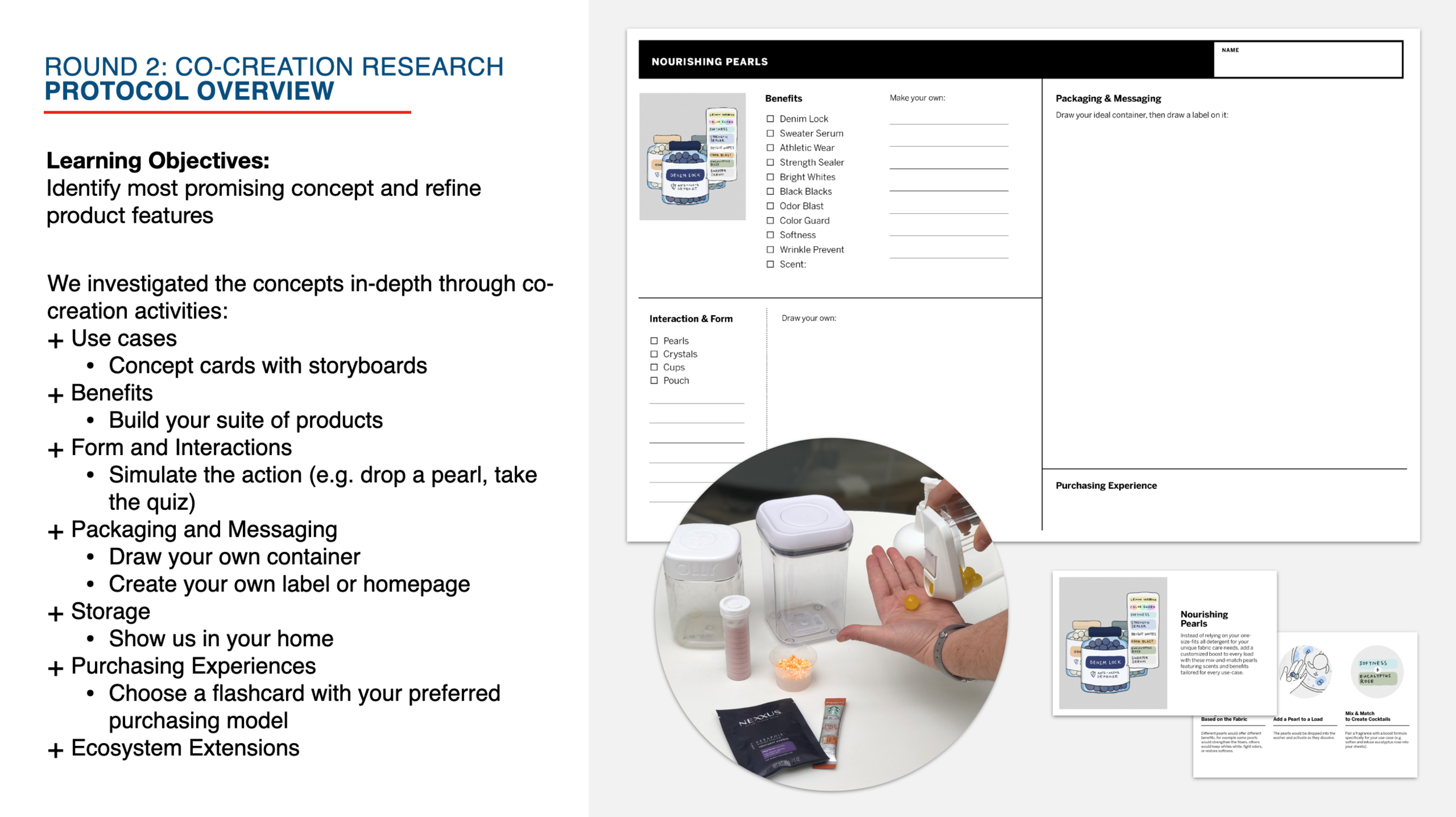

Co-creation worksheets for participants to modify and build upon their top 1 to 3 concepts. The worksheets were specific to each concept but allowed space for participants to define their ideal features and experiences of the concept.

From the concept testing, we identified and refined the most promising concept to take forward into business prototyping, where we would build out the potential features of the concept in more detail and test out options in the real world. The clear winner was Shield + Fortify, a product ecosystem that would protect your clothing from both the harm of wear and the harm of care.

prototyping a real-world business

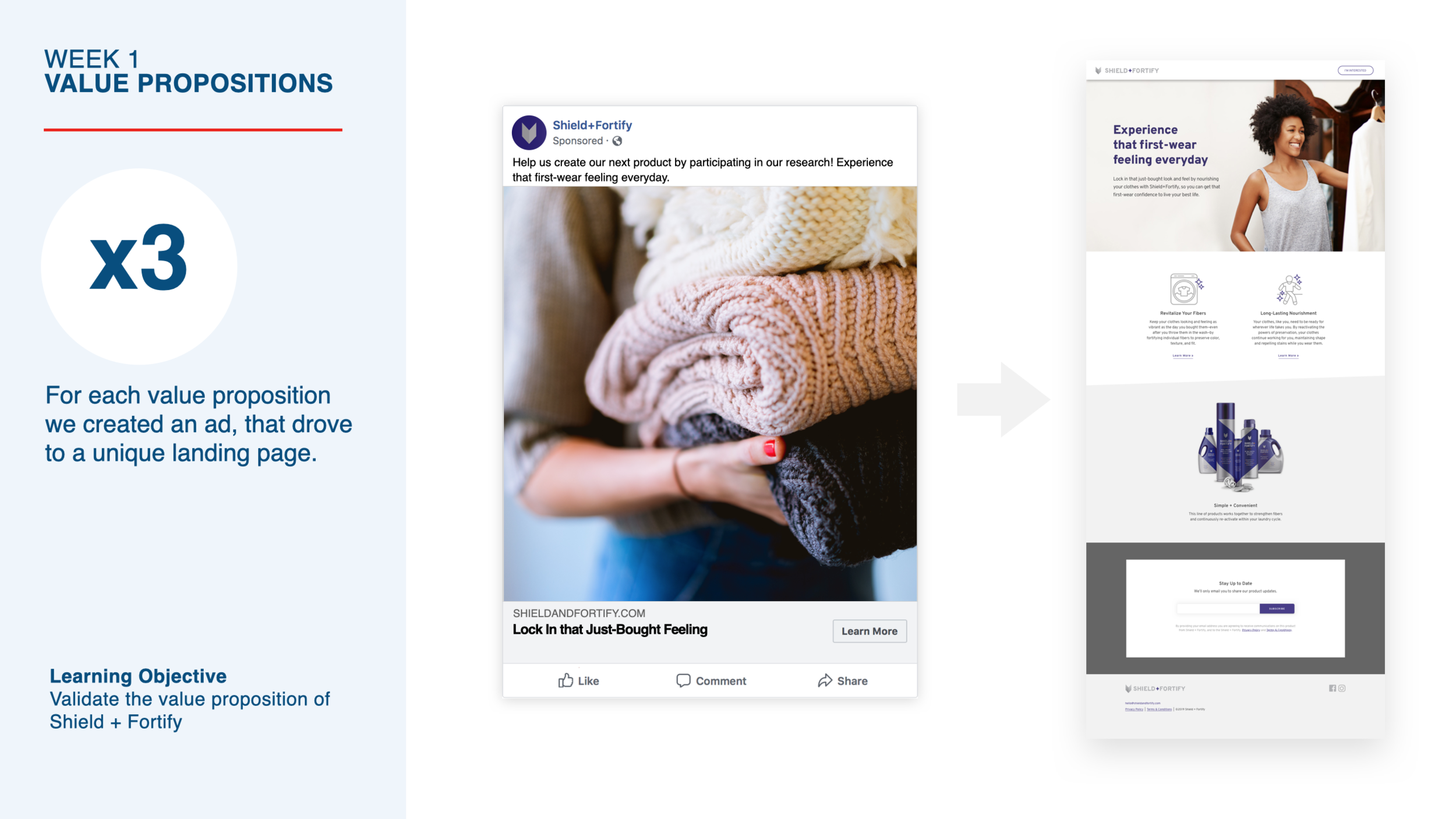

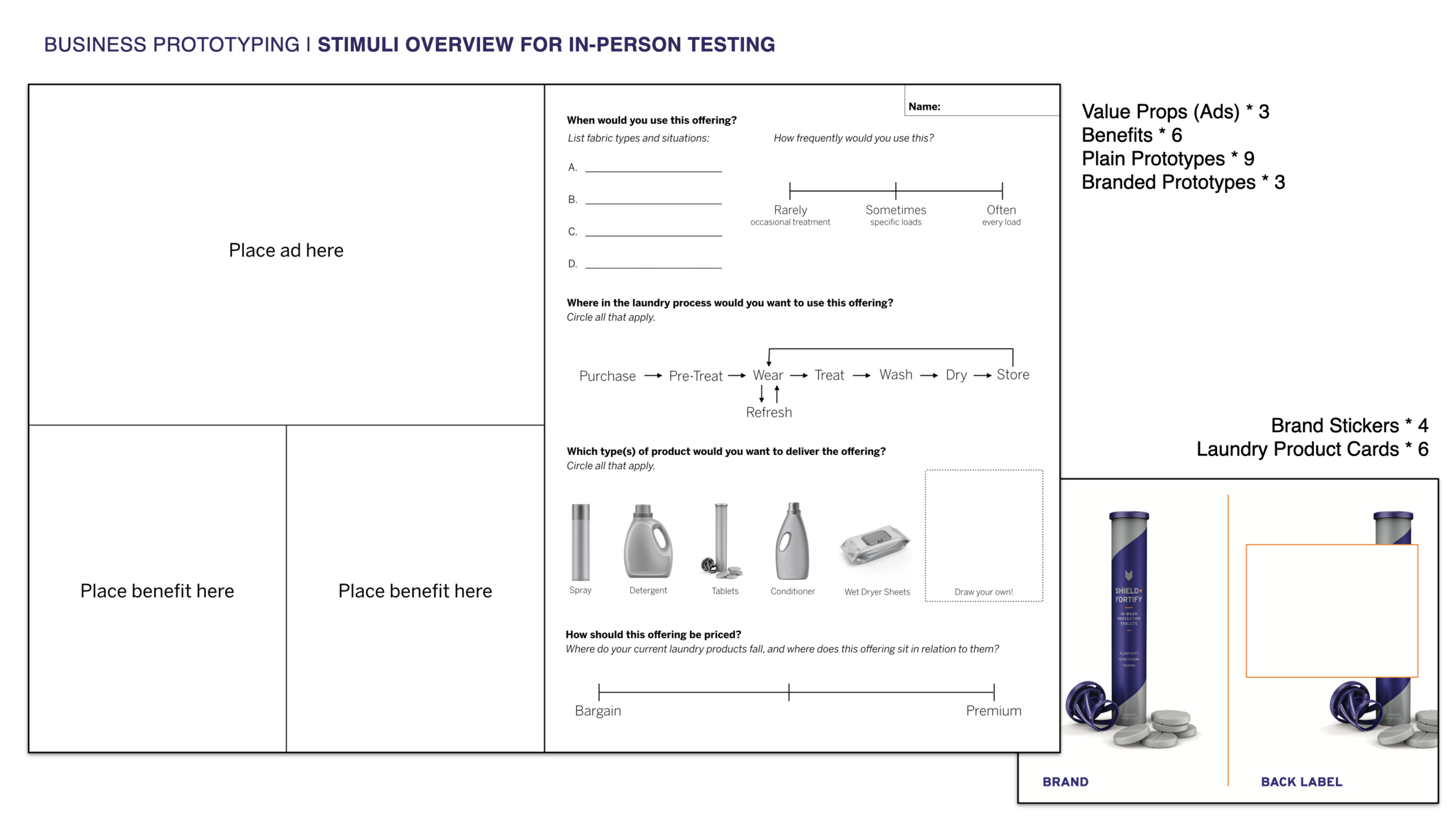

As we entered the final phase, our learning objectives were to validate the value proposition of Shield + Fortify, identify the flagship product(s) and potential ecosystem extensions, define the price tier, and establish the brand strategy.

To get to these answers, we simulated a business both online and in person to understand real behaviors. The online experiment allowed us to collect and analyze quantitative data about customers’ preferences through a series of A/B tests, while the in-person testing provided qualitative insight into the ‘why’ behind the choices we were observing.

online business: observing the ‘what’

The online A/B testing measured real customer reactions to different options for value propositions, benefits to fabrics, branding, and products (which also stood in for the stage in the fabric care journey, e.g. tablet for the wash or a refresh spray between wears). Because so many elements were being tested, we divided the tests into 2 weeks. The first week tested the value proposition and benefits; in the second week, we locked in the winning value proposition and benefits from the first week and varied the branding and products. In total, the digital testing consisted of:

3 different social media ads, each with a different value proposition, to funnel customers to different landing pages.

18 landing pages that varied the benefits, branding, and products. The pages contained “learn more” buttons under each benefit, “I like this” buttons to select products, and an email sign-up to stay informed about product launch.

We measured clickthrough rates (both on the ads and landing page buttons), time spent on each page, and email conversions. In total, our ads reached about 100,000 people, with about 5,000 clicking through to the landing pages (a 5% clickthrough rate is 10 times that of the average Instagram ad).

pop up shop and in-home parties: understanding the ‘why’

The digital testing provided data on customers’ preferences and interests. However, to understand why customers were making these choices, we paired the quantitative with some qualitative in-person testing as well.

Pop-up shop: we set up a little shop inside a grocery store, intercepting real customers in context, where they are in a shopping state of mind making real purchasing decisions. They interacted with physical prototypes and provided feedback in 10-15 minute sessions. We intercepted 20 customers in 4 hours.

In-home parties: we wanted to supplement the pop-up shop intercepts with more in-depth conversations. We recruited people from 4 different income levels and life stages to gather their friends, in groups of 4-6 people, to a 2-hour party to ‘shop’ for new laundry products. Because we had more time, the sessions were structured in a way where the participants were building their ideal product from the ground up, working through a worksheet to specify the features of their ideal product, selecting choices from plain white prototypes, and finishing with the branding exercise at the end (we wanted to avoid known brands influencing customers’ reactions or perceptions).

strategic recommendations

After synthesizing our learnings from the business prototype, we revisited our earlier capability assessment and competitive landscape analysis and conducted further market sizing for the fabric preservation platform. The results allowed us to recommend an R&D and go-to-market strategy that called for a phased roll-out of products, starting first with novel additives to establish trust with the customer followed by expansion to more traditional forms, where the big bucks really are. The new product line should first be introduced through novel additives because: (1) the new form factor invites curiosity and interest and (2) by isolating the benefit within a single-purpose additive, users are able to prove to themselves that the product really does deliver on its promise. Once the benefit is proven by the single-purpose additive, customers are more likely to believe that a traditional product, such as detergent, can in fact deliver that new benefit with the additive built in. Customers could purchase the entire ecosystem of products, which will be designed to work together to continuously reinforce the benefits at every point of the fabric care journey.

These recommendations are now being implemented by our client. The R&D timeline will take about 18 to 24 months for the first product to be released, so hopefully we will all be able to shield and fortify our clothes in 2021!

sustainability bonus!

And there’s a bonus environmental benefit: the product works by preventing the microfibers in your clothing from shedding, both in the washer and in the dryer. You know that lint you see collecting in your dryer? Well, that’s actually fibers that have broken off from your clothing—and you don’t see them in your washer because they are small enough to go out with the water when it drains (this is why your clothing thins over time). These microfibers, particularly from synthetic clothing, are polluting our oceans and end up in the stomachs of species we eat (you can read more about that here). Shield and Fortify keeps the fibers in your fabrics and out of our oceans. Not to mention that if your clothing lasts longer, you can throw away less and buy fewer replacement items, which results in less waste overall—both in the landfill and throughout the manufacturing process and supply chain.