FLAT-PACKED, EASY ASSEMBLE, PREFAB TOILET SHELTER

PRODUCT DESIGN & Development Manager, WATERSHED

CAMBODIA

OVERVIEW

THE CHALLENGE

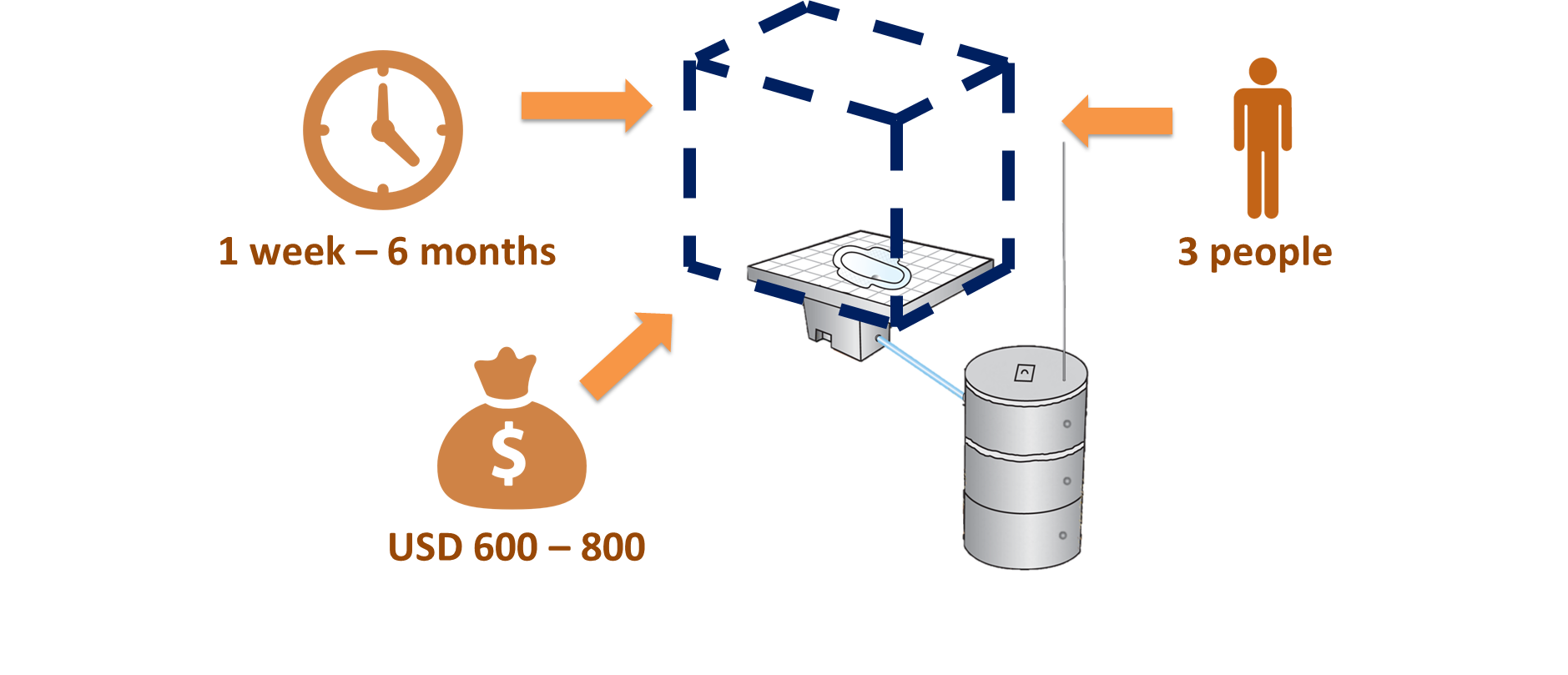

Nearly 70% of rural Cambodians still practice open defecation, which can lead to serious illnesses and hinder child development. WaterSHED conducted market research (http://ow.ly/JyL04) and found that the lack of access to desirable latrine shelters is the biggest remaining barrier to achieve total sanitation. The conventional brick shelter costs $600 - $800 and requires about 10 days labor. For those who cannot afford hired labor, construction often takes months to complete. Currently, the long and difficult construction process not only delays latrine adoption for those who have committed to building a toilet but, consequently, deters neighbors from purchasing one.

Objectives:

Remove barriers to toilet adoption for consumers in rural Cambodia

Boost the profits of WaterSHED's rural business partners through increased sales of toilets

STAKEHOLDERS

Target customers: rural Cambodian households

Rural business partners

Construction workers and installers

Salespeople

Community leaders, such as village chiefs

Marketing team

APPROACH

Ethnographic Research & Co-creation: immersion/observation, surveys, in-depth interviews, focus group discussions, co-creation workshops

Prior Art Evaluation: review of existing technologies and products - do they meet our stakeholders' needs?

Iterative Prototyping & Testing: designed and built many iterations of prototypes, from low- to high-fidelity; tested with all stakeholders

Design for Manufacturing: failure modes & effects analysis (FMEA), assessment of manufacturers, supply chain analysis

OUTCOMES

Our design is the first durable household toilet structure for rural markets to be prefabricated, lightweight, flat-packed, and easy to assemble. The shelter can be installed without electricity or special tools or equipment; mass production ensures quality control and allows for rapid scale-up; flat-packing minimizes transport and storage costs. Our shelter slashes prices in half and cuts installation time from 10 days to 1 day. The shelter underwent a pilot with test marketing from mid 2016 to early 2017 and was launched on the Cambodian market in April 2017. Since its launch, our rural business partners’ toilet sales have doubled to over 200,000 units, expanding access to sanitation to 1 million Cambodians.

RECOGNITION

Finalist, American Society of Mechanical Engineers' Innovation Showcase, 2015 and Sankalp Southeast Asia Awards, 2016

ETHNOGRAPHIC RESEARCH AND CO-CREATION

methods

Initial research into barriers to toilet adoption:

Survey of 700 households

In-depth interviews with customers, rural business partners, salespeople, and construction workers

Targeted observation (e.g. observing purchase and installation of shelters)

Further research to inform product design:

Survey with business partners about their capabilities, resources, and constraints

In-depth interviews with business partners and customers

Focus group activities with customers

Co-creation workshops with business partners, installers, and customers

Testing many iterations of prototypes, from low to high fidelity, with customers, partners, and installers

key insights

Greatest barrier: people will not purchase a toilet without a shelter to go with it

People aspire to purchase brick shelters, but they are too expensive to purchase and too labor-intensive and time-consuming to install

People do not buy cheaper thatch shelters, because they are unattractive, hard to clean, and fall apart

People choose to continue open defection until they can afford the brick shelter

Further insights, by stakeholder:

Business partners and installers:

Inconsistent labor supply (labor seasonally migrates to Thailand)

No capital for new product fabrication

Unreliable, nonexistent, or expensive electricity

Variable storage space

No heavy lifting equipment (e.g. cranes)

Customers:

Want more than a toilet – want a bathroom, with space for water tank and bathing

“Too poor to buy a cheap product twice” – can’t afford to buy a new shelter every few years

Shelter should signify wealth and modernity to neighbors and visitors from the city (primary motivator for toilet and shelter purchases)

Clean surfaces mostly with water, sometimes with laundry detergent

insights to actions: iterative Prototyping and testing

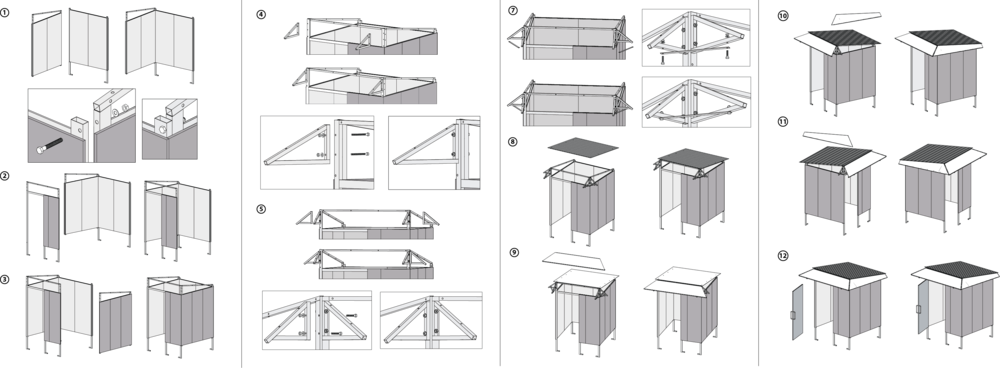

The research described above revealed a market opportunity for a mid-range shelter: a shelter as desirable as--or more desirable than--the brick shelter, but at a more affordable price. The shelter would be sold along with the toilet as a single complete package, and costs would include installation. Our research informed the following product requirements for the shelter, and we designed and built many iterations of prototypes, of increasing fidelity, to fulfill these requirements (see pictures, above). We tested each iteration with customers, business partners, and local construction workers until we had the best possible first-generation product.

product requirements

Prefabricate shelter in central facility (because business partners do not have the capacity for distributed production)

Flat-pack to reduce transport and storage costs

Eliminate power tools for on-site assembly (due to unreliability of electricity)

Shelter must be large enough to accommodate bathing space

Durable frame for long lifetime

Exterior should appear "modern" and "beautiful" by Cambodian tastes

For the interior, an affordable alternative to tile that is easy to clean

design for manufacturing and supply chain

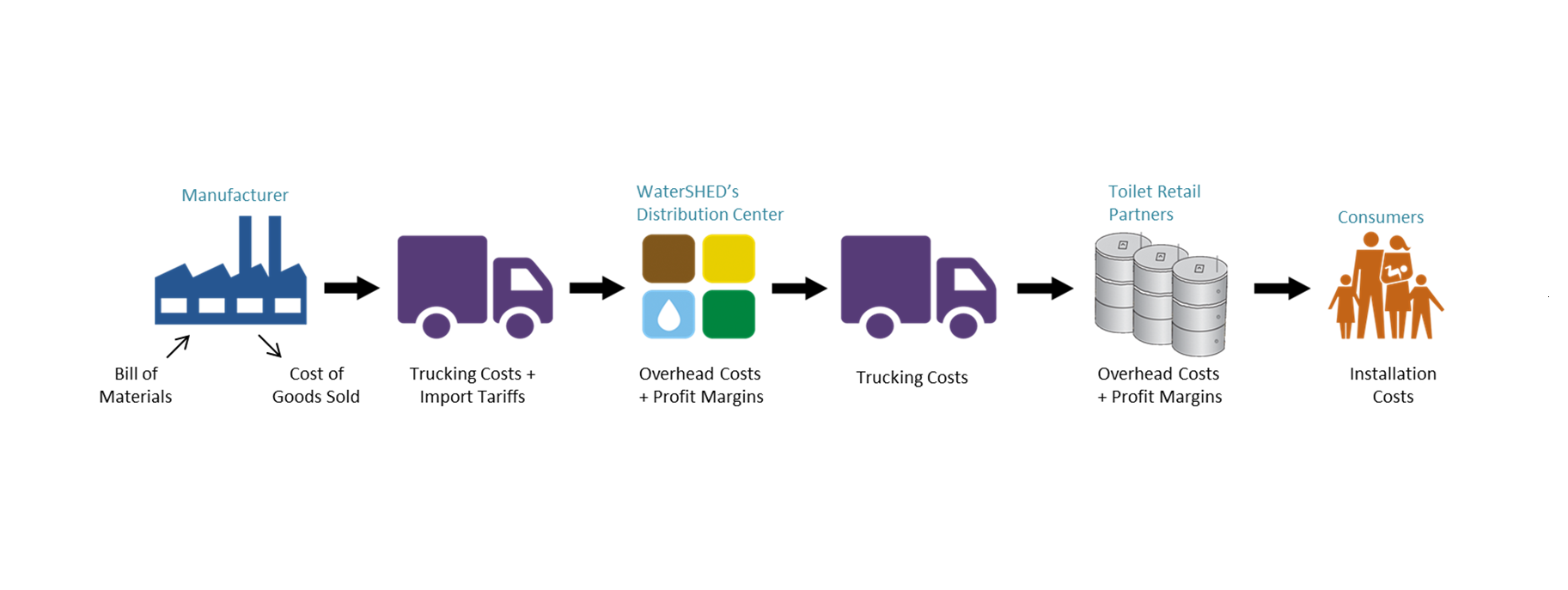

To make the shelter production- and market-ready, we had to incorporate design for manufacturing and consider supply chain costs and limitations:

We conducted Failure Modes and Effects Analysis (FMEA) to identify and address risks.

For example: FMEA brought attention to the potential for rust. Shelter owners would need to maintain their steel frames. We removed interior panels so owners could recoat frames easily. To maintain aesthetic appeal, we painted frames in fun colors that match patterns of vinyl wall coverings and tested with customers (see photos, above).

We sent engineering drawing packages and bill of materials (BOM) to manufacturers in Thailand and China to gather quotes, and we visited factories and negotiated with the top contenders. We also used the manufacturers' feedback about our design to make the shelter easier to assemble in the factory.

To set the price of the shelter, we incorporated supply chain considerations—including what profit margins would motivate our rural business partners to push sales. Additionally, the supply chain costs helped us to choose a manufacturer in Thailand rather than China. Even though the cost of goods sold (COGS) was lower in China and it is cheaper to ship by sea from Shenzhen than overland by truck from Bangkok, the import tariffs from Thailand are much lower than from China due to regional trade agreements.