off-grid irrigation pump for smallholder farmers

MASTER'S THESIS, MIT TATA CENTER FOR TECHNOLOGY & DESIGN

JHARKHAND, INDIA

OVERVIEW

The challenge

Smallholder farmers without electricity access in eastern India cannot afford to irrigate their lands due to high operation costs of fuel pumps. As a result, these farmers grow few or no crops and may migrate for work. When they migrate to other states, their families cannot access social services (e.g. education, health). This project aimed to address this challenge by designing a pumping system with lower operation costs, so that farmers could afford to irrigate their land and grow crops during the dry season. I worked with PRADAN in Jharkhand.

STAKEHOLDERS

Farmers who rent pumps

Farmers who own and rent out their pumps

Pump manufacturers

Pump retailers

Mechanics

Community leaders

Local NGOs (e.g. PRADAN)

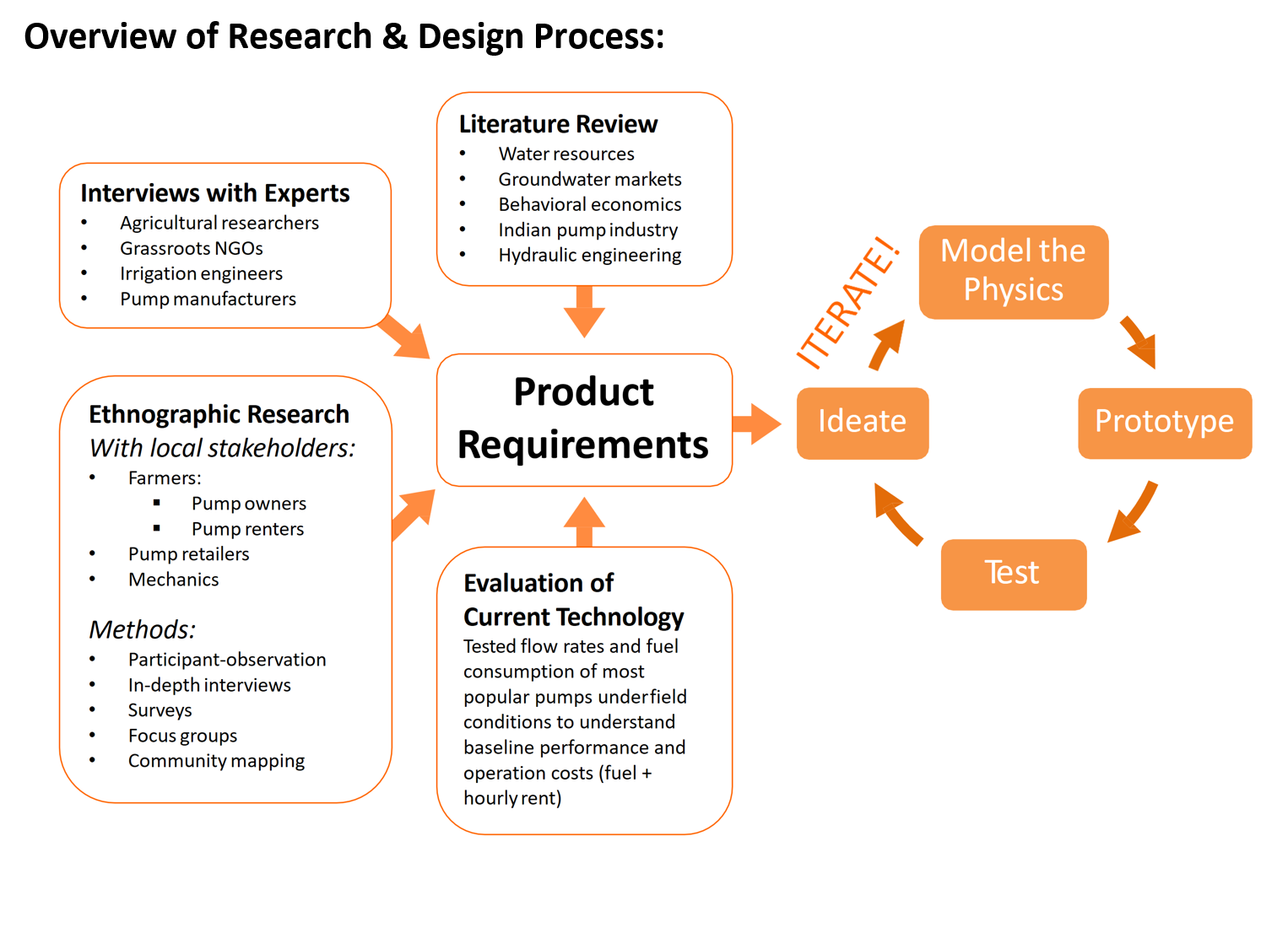

Approach

Consultation with Experts: agricultural economists, anthropologists, irrigation engineers

Ethnographic Research: immersion/observation, in-depth interviews, survey, focus group discussions, community mapping, seasonal diagramming

Technology Evaluation: tested most popular pumps on Indian market for performance and operation costs

Rapid Prototyping & User Testing: sketching, CAD (Solidworks), "looks-like" and "works-like" prototype tested with users

outcomes

My research laid the foundation for further product development taken forward by the MIT Tata Center and start-up Khethworks. The partnership I established with PRADAN is ongoing.

links

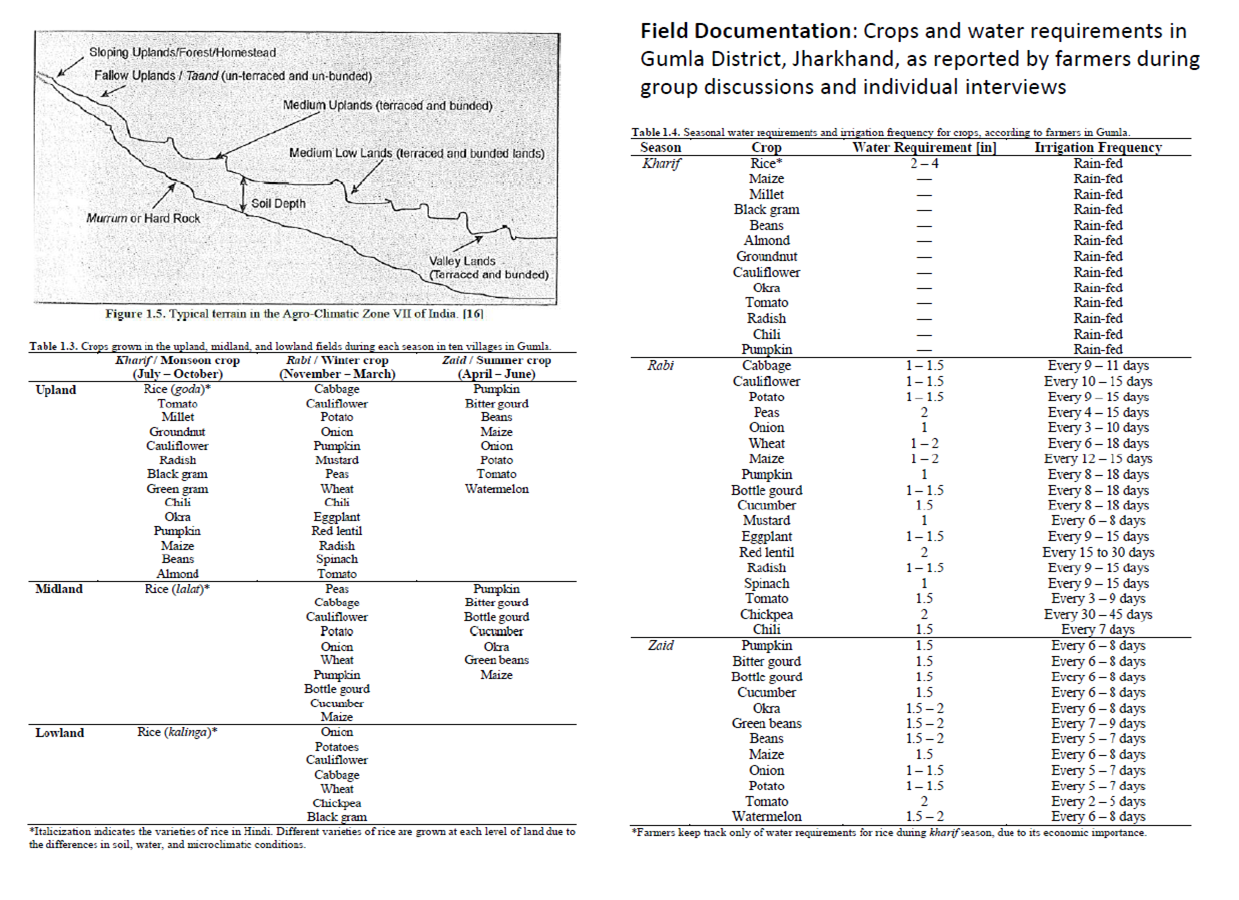

ETHNOGRAPHIC RESEARCH

methods

Immersion and observation of irrigation practices and pump maintenance

Participatory community mapping of water resources and crop fields

Seasonal diagramming of crop cycles and water requirements

In-depth interviews with farmers (both pump owners and pump rentals), pump manufacturers, retailers, mechanics, NGOs, government, community leaders

Survey with farmers

Focus group discussions with co-creation activities

key insights

Farmers rent pumps on hourly basis from a handful of wealthier neighbors who own pumps. These pump owners band together to form an oligopoly and fix high rental rates. Rented pumps are transported to wells by bicycle.

Fields can be very far from the well. This requires long hoses, which means reduced energy efficiency and higher fuel costs.

Due to the high costs of irrigation, farmers rely mostly on rain and irrigate only (a) during a poor monsoon or (b) for tiny subsistence plots of vegetables during the dry season.

Broken pumps are repaired by local motorcycle mechanics.

People worry about theft and store valuable machinery inside their homes.

Women are not allowed by husbands to operate machinery (e.g. engines), and struggle to collect water for household purposes

Manual rope pumps in neighboring state of Orissa that had been installed purposefully for irrigation were actually being used for domestic water needs

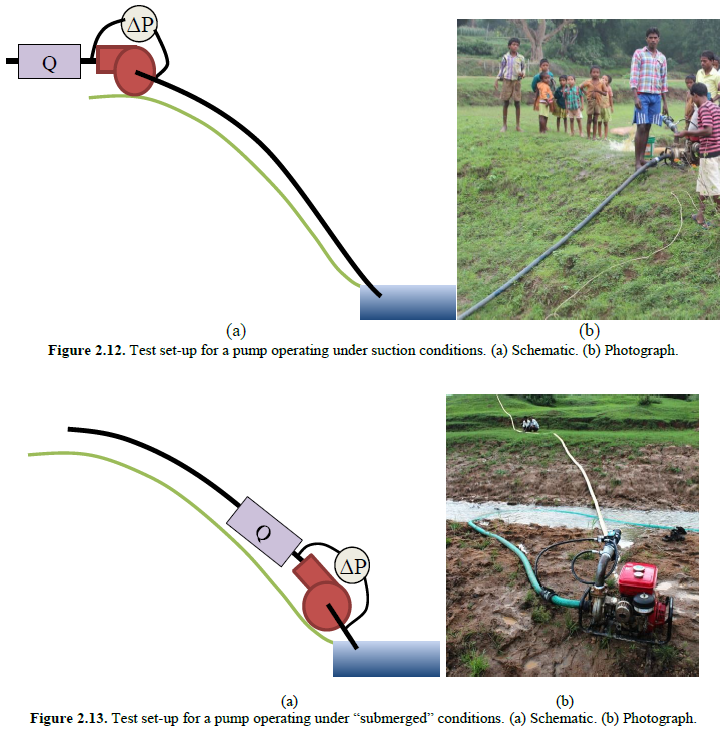

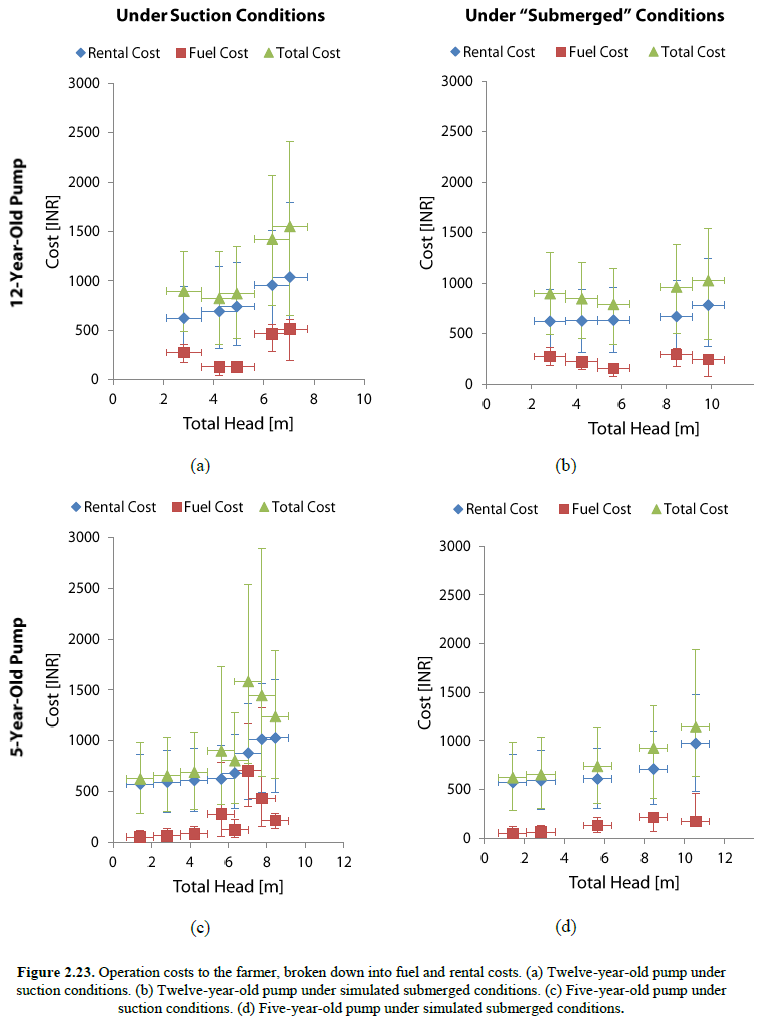

TECHNOLOGY EVALUATION: ESTABLISHING BASELINE PERFORMANCE & COSTS

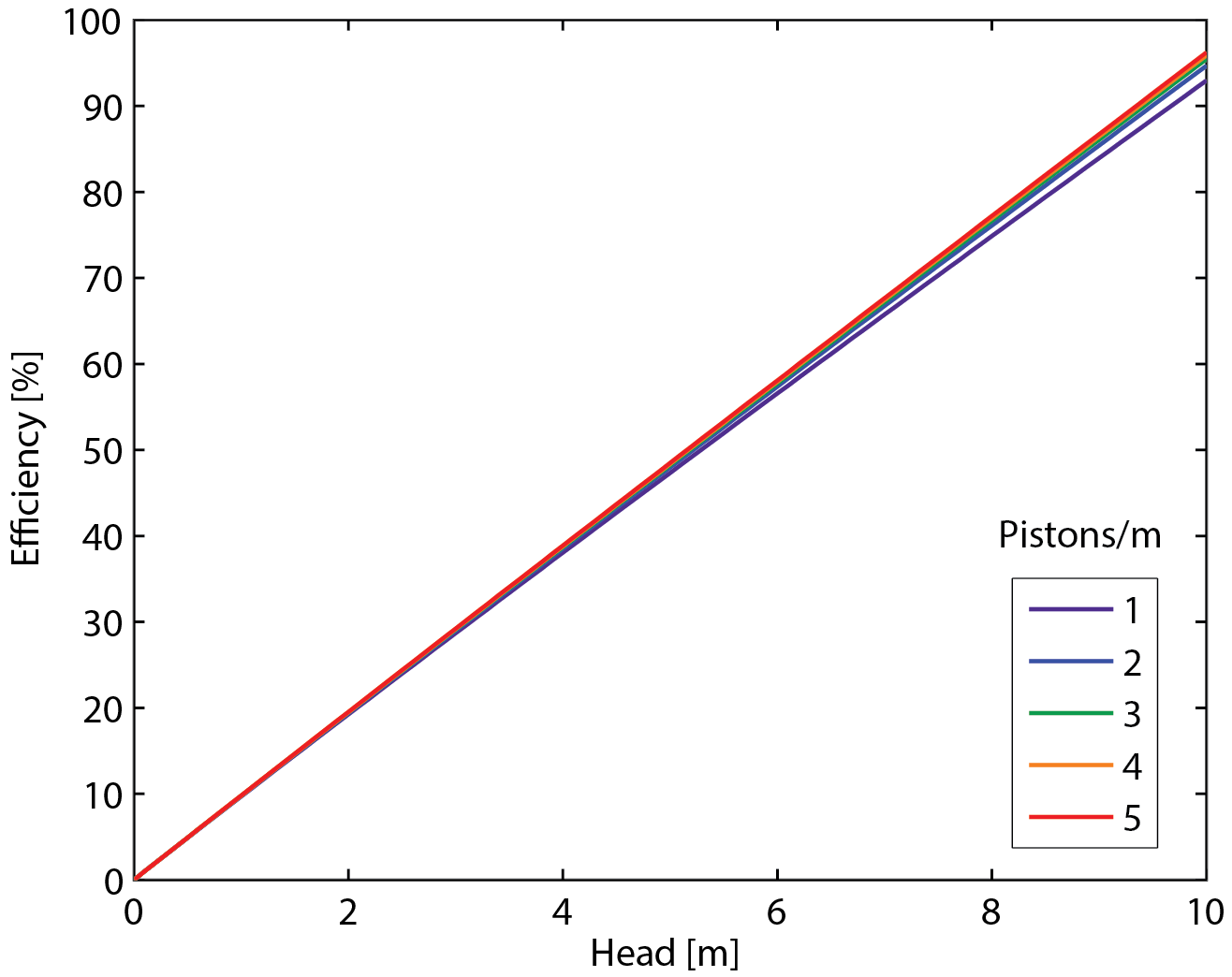

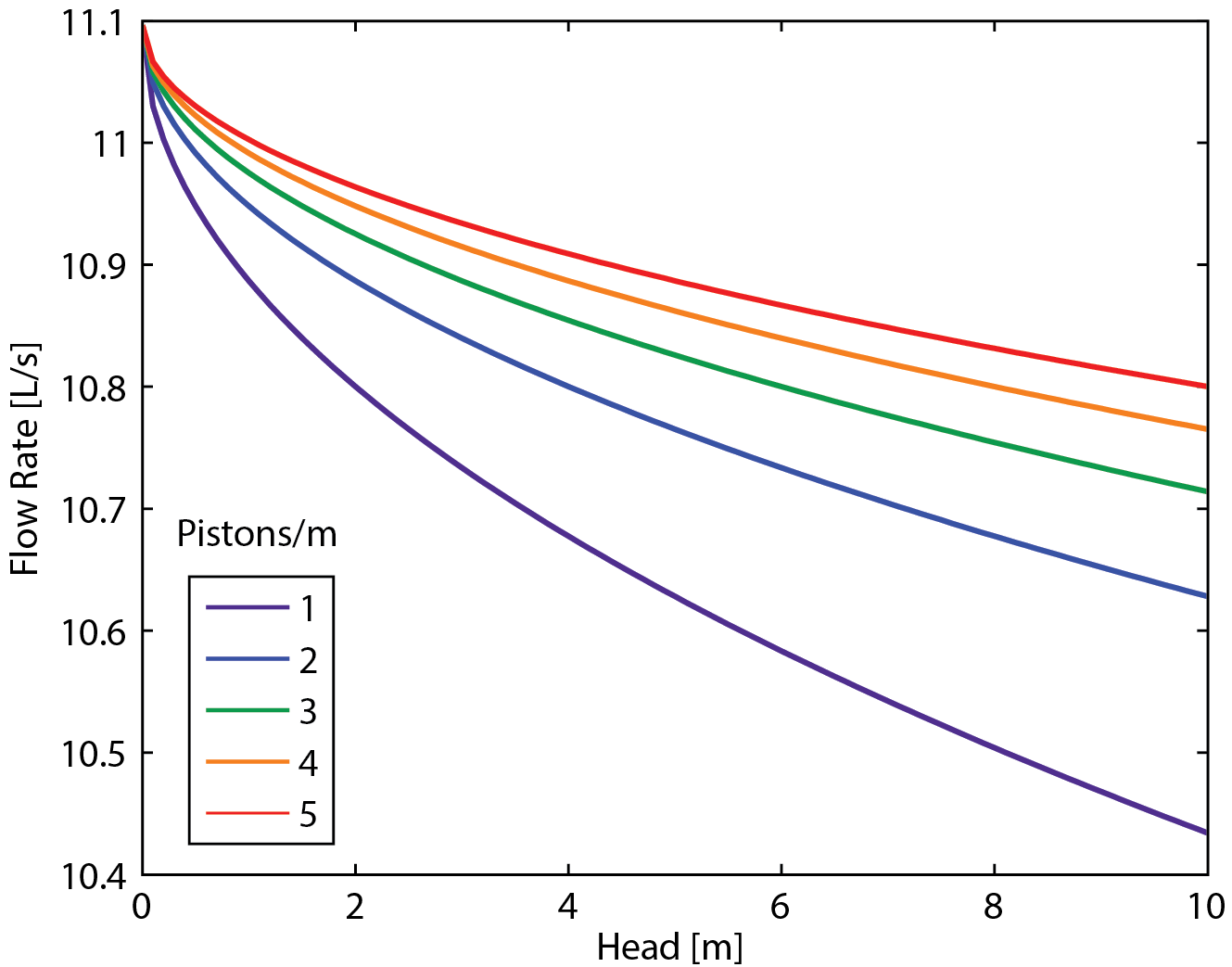

I tested the most popular pumps on the Jharkhand market in order to (a) establish baseline performance (flow rates, fuel consumption) and operation costs and (b) test the hypothesis that removing suction lift would reduce operation costs. I found that eliminating suction head can decrease operation costs up to 44% for the farmers. Interestingly, this decrease in costs is impacted more greatly by the difference in flow rates than by the difference in fuel consumption, because the hourly rental fee for a pump is greater than fuel costs. A lower flow rate means more hours required to irrigate a certain amount of land, so increasing the flow rate reduces hourly rental costs. This finding reframes the energy efficiency question for a new pump technology: how might we increase flow rate in order to decrease rental costs?

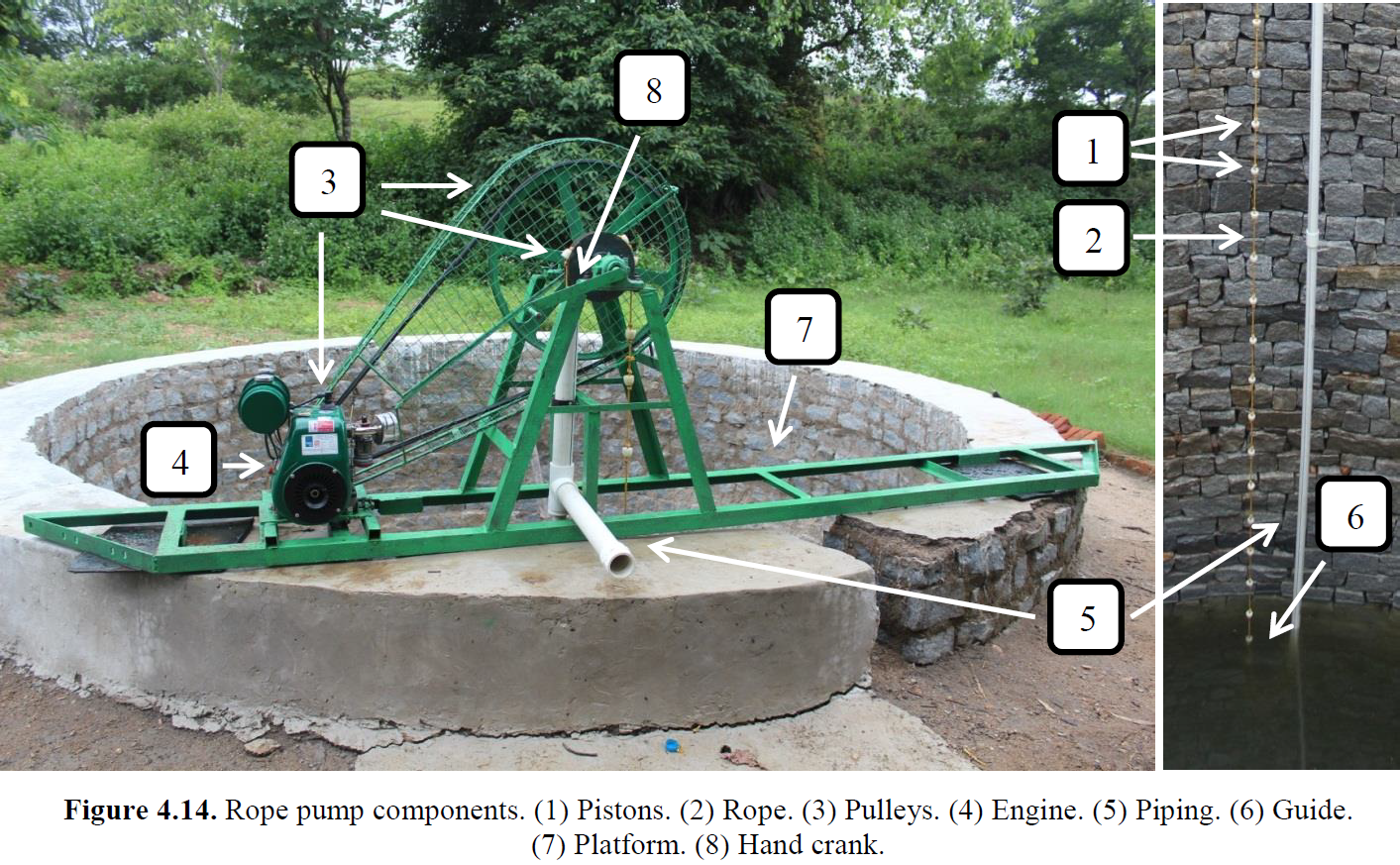

HYbrid motorized-manual rope pump: DESIGNING & TESTING PROTOTYPE

INSIGHTS TO ACTION: PRODUCT REQUIREMENTS

I designed and built a rope pump prototype that met the following product requirements informed by the above ethnographic research and technology evaluation, and then tested the prototype with users.

In order to address water needs for both domestic and farm use and to ensure women could also use the pump, the pump should have two modes: manual for low-flow applications (domestic uses) and motorized for high-flow applications (farm use).

Engine must be removable so that (a) one engine can be rented out to multiple wells and (b) engines can be stored inside homes to prevent theft. The engine must be lightweight enough to be transportable by bicycle.

Hand crank must be removable for safety during motorized operation.

Pump must be made from parts locally available to motorcycle mechanics for easy repair and replacement.

moving forward

A number of changes can be made to improve the performance and usability of this pump (see video, below). However, this solution would be difficult to scale due to issues associated with shipping and installing such a large machine and the need to custom-fit the pump to each well. A more scalable solution would require more intensive R&D to investigate how to improve the efficiency of a centrifugal pump (the MIT Tata Center students who took this project forward have followed this recommendation). Another solution might be to disrupt the pump rental market with an Uber-like sharing economy platform (such as Hello Tractor’s model for agricultural equipment in Nigeria) or an irrigation-as-a-service business.